Dec 15, 2025

Vital Parts in Heavy Machinery Engines

Author: burak.karaduman

Heavy machinery operates in challenging environments such as construction, mining, and agriculture, and its engines must withstand these conditions. There are key components that directly affect an engine's power, efficiency, and durability. The failure of these components can lead to the entire machine stopping and significant costs. Every component in an engine is crucial; even the smallest component malfunctioning can affect the entire engine. Understanding this is crucial. We can't cover every component individually in this article, but let's take a look at a few to see their benefits. 1. Pistons and Connecting Rods (Connecting Rods) The heart of the engine is where combustion takes place. Pistons move within the cylinder, converting the energy of the explosion in the combustion chamber into mechanical motion. Importance: They are the main element that transmits the explosion force directly to the crankshaft. They must be resistant to high temperatures, ...

Nov 07, 2025

The Power Behind Quality: ÜÇ ASLAR and Its ISO Certifications

Author: burak.karaduman

Today, quality is no longer defined solely by a product — it is measured by a company’s management approach, production processes, and relationship with its customers. Since 1960, ÜÇ ASLAR has placed this philosophy at the heart of its corporate culture, setting industry standards with its production approach fully compliant with international ISO standards. Proving Quality Through Process, Not Paper At ÜÇ ASLAR, quality is not a goal — it is a way of life. From the design stage to delivery, every product is meticulously monitored in accordance with the ISO 9001:2015 Quality Management System, ensuring not only flawless production but also long-term sustainability. In addition, certifications such as AS9100D Aerospace Quality Standard, ISO 14001:2015 Environmental Management, ISO 10002:2014 Customer Satisfaction Management, and QHSAS 18001:2007 Occupational Health and Safety reflect our deep commitment not only to product excellence but also to our responsibility toward the ...

Jul 25, 2025

The Unsung Heroes: Understanding Bogie Systems in Heavy Machinery

Author: burak.karaduman

At its core, a bogie is an independent assembly of wheels or tracks that supports a portion of the machine's weight and provides articulation, allowing the machine to navigate uneven surfaces without putting undue stress on the main chassis. Think of it as a specialized, heavy-duty suspension system designed for the most demanding environments. The Front Bogie The front bogie is often the workhorse when it comes to steering and initial load distribution. In many heavy machines, especially those designed for high-speed travel or precise maneuvering, the front bogie plays a pivotal role in directing the machine's path. Steering Mechanism: Unlike the simple pivot of a car's front axle, a front bogie can incorporate complex steering geometries, sometimes with multiple steering axles or even individual wheel steering. This allows for tighter turning radii and improved maneuverability in confined spaces. Weight Distribution: It's the first point of ...

Jun 24, 2025

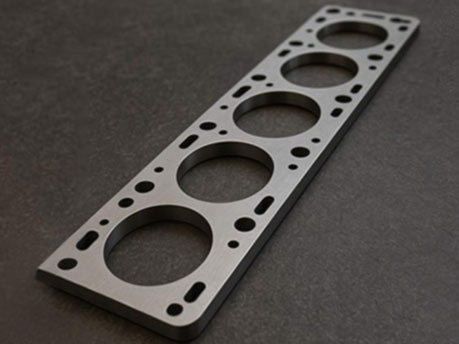

What is an Engine Spacer Plate?

Author: burak.karaduman

At its core, an engine spacer plate is a precision-machined piece of material, typically aluminum or steel, that is designed to be installed between two major components in the drivetrain. Most commonly, it's found between: The engine block and the transmission bell housing: This is where they earn their "engine spacer" moniker, as they literally create space between these two crucial parts. Other mounting points: In some custom applications, they might be used to space out other components like superchargers, alternators, or even body mounts. One of the most popular plates are 6I4421,7N8021,7N7998, 2603904, 1106994 and others. All of them are used in different engines, you can find this info at our website. Click here to check Ucaslar’s best engine spacer plates. Their thickness can vary from a few millimeters to several centimeters, depending on the specific application ...

Jan 08, 2025

Goetze Mechanical Seals: Leading Technology in Sealing Solutions

Author: burak.karaduman

Goetze is one of the leading brands in sealing solutions worldwide. It is preferred in many sectors with its wide product range and innovative technologies in the field of mechanical seals. Mechanical seals, designed specifically to prevent liquid and gas leaks in switchgears that rotate or move back and forth, play a critical role in the efficient operation of equipment. Features and Advantages of Goetze Mechanical Seals Goetze mechanical seals are the industry leader in durability and performance. Its’ highlights are as follows: High Performance Goetze mechanical seals offer long service life and high performance thanks to wear-resistant materials and advanced design features. This ensures maximum efficiency in sealing solutions. Wide Range of Products There is a wide range of mechanical seal options suitable for different working conditions and application areas. This diversity caters to the specific needs of the sectors. Special Designs ...

Nov 06, 2024

Track Chain: The Key to the Strength and Movement in Construction Machinery

Author: burak.karaduman

In order for construction machines to work robustly and efficiently, many parts must work in harmony. One of the most critical thing among these parts is the track chain. Chain is one of the basic components that provides mobility, especially in tracked construction machinery. A high-quality walking chain is needed for the smooth and effective operation of the pallet system on which the machine moves. While the track chain provides mobility by carrying the entire weight of the machine, it is also designed to be strong enough to withstand harsh conditions. The Importance of the Track Chain in Construction Machinery In construction machines, undercarriage track chain ensures smooth progress in the work area by ensuring the movement of the machine. These chains make it possible for construction machines to move in various ground conditions without losing balance and control. The robustness of the walking chain is of great importance for ...

Oct 01, 2024

Machining: The Power of Precision Manufacturing in Industry

Author: burak.karaduman

Machining is an important production method that serves to obtain the desired shape by processing metal and other hard materials. This method is performed by cutting off the excess material and leaving only the part that is needed. Especially the types of enterprises engaged in machining manage this production process efficiently and play a major role in projects that require high precision. Thanks to this method, production errors are reduced to a minimum while producing high-quality parts. CNC Machining CNC machining is a more advanced and automated version of the traditional machining method. Thanks to computer-controlled machines, it is ensured that the parts are produced more precisely and flawlessly. CNC machines offer a great advantage for machining enterprises because these machines produce complex designs quickly and accurately. From automotive to aviation, CNC machining finds a wide range of applications in many sectors. At the same time, this ...

Sep 10, 2024

Aluminum and Bronze Gears: Strong and Durable Solutions in Construction Machinery Spare Parts Selection

Author: murat.tureli

Advantages of Aluminum Gears Aluminum gears are widely preferred in many sectors due to their light weight and durability. These gears ensure fast and efficient operation, especially of moving parts. The lightweight structure of aluminum helps construction machinery to perform high performance by consuming less energy. Especially big brands such as Caterpillar®, Komatsu®, Hitachi® and Kawasaki® benefit from these gears, which increase efficiency while saving energy. These lightweight gears offer an excellent solution for construction machines to cope with heavy loads. In machines where aluminum gears are used, the replacement of spare parts is also easier and faster. This reduces operational interruptions to a minimum. Durability of Bronze Gears Bronze gears are known for their high durability and wear resistance. Ideal especially for heavy duty machines, these gears maintain their performance for a long time even in harsh conditions. The hard and durable structure of ...