Vital Parts in Heavy Machinery Engines

Heavy machinery operates in challenging environments such as construction, mining, and agriculture, and its engines must withstand these conditions. There are key components that directly affect an engine's power, efficiency, and durability. The failure of these components can lead to the entire machine stopping and significant costs.

Every component in an engine is crucial; even the smallest component malfunctioning can affect the entire engine. Understanding this is crucial. We can't cover every component individually in this article, but let's take a look at a few to see their benefits.

1. Pistons and Connecting Rods (Connecting Rods)

The heart of the engine is where combustion takes place. Pistons move within the cylinder, converting the energy of the explosion in the combustion chamber into mechanical motion.

Importance: They are the main element that transmits the explosion force directly to the crankshaft. They must be resistant to high temperatures, pressure, and friction.

Connecting Rods: These are critical connecting parts that convert the linear motion of the piston into the rotary motion of the crankshaft.

You can find more information and parts here.

2. Crankshaft (Main Shaft)

This is the component that regulates the power generated by the engine to transmit it to the wheels or construction equipment.

Importance: It is the backbone of the engine, collecting the power from all the pistons and transferring it to the transmission. It is subject to extreme loads, torsion, and vibration. Therefore, precise balancing is essential for the long life of the engine. You can view all UCASLAR crankshafts here.

3. Cylinder Block and Cylinder Head (Head)

These two structures form the main body of the engine and house all other components.

Cylinder Block: This is the fundamental structure that houses the cylinders in which the pistons move. Cooling water channels and lubrication channels are also located within this block.

Cylinder Head (Head): Mounted on the cylinder block, it forms the upper part of the combustion chamber. The valve mechanism, spark plugs (gasoline) or injectors (diesel) are located on this head. Sealing the engine with a gasket is vital.

4. Valve Train (Valves) and Camshaft (Camshaft)

This is the system that allows the engine to "breathe."

Valves: Intake and exhaust valves control the intake of the air/fuel mixture into the combustion chamber and the exhaust of exhaust gases. Opening and closing them at the correct time and in the correct amount is the foundation of engine efficiency.

Camshaft: This is the main component that controls the timing and duration of valve opening and closing (valve timing). This timing directly determines engine performance and fuel efficiency.

5. Fuel System Components (For Diesel Engines)

The vast majority of heavy machinery uses diesel engines, and the components of this system are critical.

Injectors: Inject fuel into the combustion chamber at high pressure and with precise atomization. Common Rail injectors used in modern engines directly affect the engine's power, emissions, and efficiency.

High-Pressure Pump: This is the key component that generates the extremely high pressure (thousands of bar) required to deliver fuel to the injectors.

As the UCASLAR family, we have been successful distributors of the renowned Italian company DISA for the past five years, providing a wide variety of parts. Various pumps, nozzles, caps, and more.

You can find all the parts here.

In Summary: Why Are These Parts Most Important?

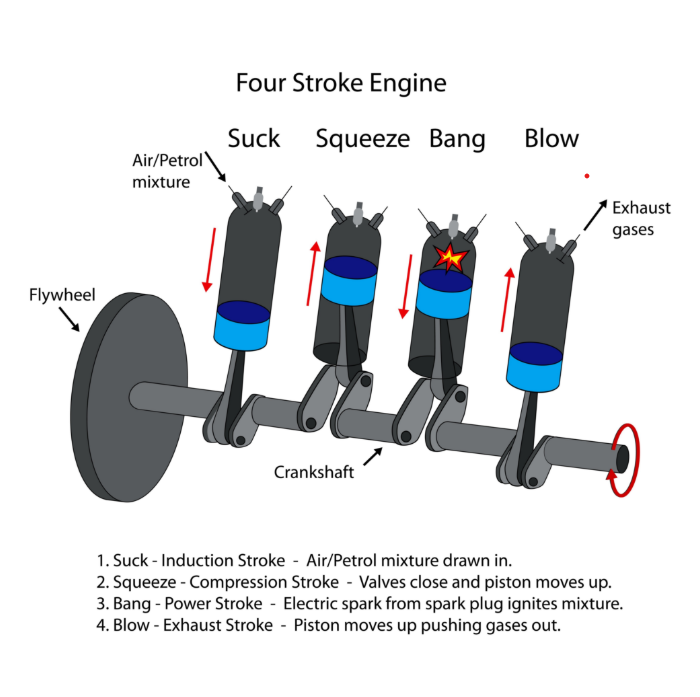

These parts are the main structural components that carry out the engine's basic four-stroke cycle (intake, compression, combustion/work, and exhaust), and are subjected to high forces, temperatures, and pressures. A malfunction in any of these parts can result in the engine's lack of power, overheating, or permanent damage.

For the longevity and reliability of heavy machinery engines, regular maintenance inspections of these key parts and, when necessary, replacement with quality spare parts are vital.