What is an Engine Spacer Plate?

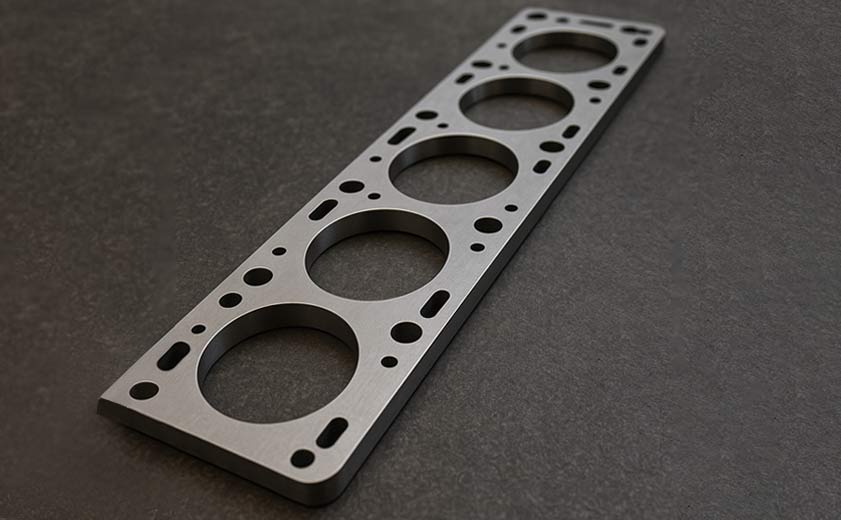

At its core, an engine spacer plate is a precision-machined piece of material, typically aluminum or steel, that is designed to be installed between two major components in the drivetrain. Most commonly, it's found between:

One of the most popular plates are 6I4421,7N8021,7N7998, 2603904, 1106994 and others. All of them are used in different engines, you can find this info at our website.

Click here to check Ucaslar’s best engine spacer plates.

Their thickness can vary from a few millimeters to several centimeters, depending on the specific application and the amount of spacing required.

Why Do You Need an Engine Spacer Plate?

The need for an engine spacer plate usually arises when you're trying to fit components that weren't originally designed to work together directly. Here are the most common reasons:

- Transmission Swaps & Adapters: This is perhaps the most frequent use case. If you're swapping a different transmission into a vehicle, or using an adapter plate to mate a non-original transmission to your engine, you might find that the input shaft of the transmission doesn't quite reach the crankshaft pilot bearing, or that the bell housing fouls on the engine block. A spacer plate remedies this by pushing the transmission further back, ensuring proper engagement and preventing damage.

- Crankshaft-to-Torque Converter/Clutch Alignment: In automatic transmissions, the torque converter needs to sit correctly within the bell housing and engage with the flexplate on the engine. For manual transmissions, the clutch disc and pressure plate need precise alignment. A spacer plate helps maintain this critical alignment, preventing premature wear on bearings and input shafts.

- Flywheel/Flexplate Clearance: Sometimes, after installing a new flywheel or flexplate (especially aftermarket or performance-oriented ones), you might encounter clearance issues with the starter motor or other components. A thin spacer plate can often provide just enough extra room.

- Component Relocation (Less Common for Engine Spacers): While not the primary function of an engine spacer plate, the concept of spacing is also used in other areas of custom builds to move components for clearance or routing purposes.

Key Considerations When Using an Engine Spacer Plate:

Visit our instagram and check new posts:

https://www.instagram.com/p/DLCVC44sfvJ/?igsh=bWFubzVnbjhxaWNy